Product: Dragéekíss TM

Problem to be solved: A Pearl cake applicator to decorate cakes.

Inventor: Gwen Powell and Angelique Meyer.

Company: Dragéekíss Ltd

We are delighted to say that the Drageekiss (DK) is now a success having had an enormous impact in the cake industry and cake art internationally with global recognition from cake artists, bakers and teachers falling in love with the pearl applicator. The Drageekiss is being sold all over the world by distributors and online. Version 2 of the DK is on the way.

Dragéekíss Ltd approached us with a simple idea, Angelique is a professional baker and tells her story like this:

“I am sure every baker will relate to my story…Most of our incredible pieces of art are made later at night, when our families are fed and in bed. So, late one night I was busy decorating a square 4-tier white wedding cake with quilting and a flower bouquet in the one corner. I started adding my dragées (the name for edible pearls) to the cake and every second one dropped on the floor, my fingers got sticky from the icing and edible glue and after a while this caused the balls to loose colour; the silver transferred onto the white cake and my nails poked holes in the cake every now and then… I had to get up and wash my fingers after every 10th dragée and it took me almost 2 hours to finish adding all the dragées; another 30 minutes were spent with a tweezer to remove the dragées that dropped into the flower bouquet and to clean the silver spots on my white cake…”

Angelique the Drageekiss inventor

Eventually I was done and my cake looked gorgeous; I could pack everything away, clean up and go to bed like the rest of the family… but then, every baker out there’s worst nightmare happened… I dropped the whole container of dragées on the floor and those little balls rolled everywhere. In South Africa ants love sugar and if your floors are not kept spotless then you will get an ant infestation overnight. So, I dropped to my knees and started picking up all these little balls… when it hit me – a tool to keep these balls in place!

Container of dragees

That’s when she had the idea! A pearl cake decorating device that contains the pearls and injects them out onto the cake. Angelique had started a proof of principle prototype at home, and Gwen brought us a few of the early prototypes.

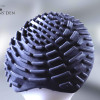

development of prototypes

The first prototypes at the top were the ones brought to us by Gwen that Angelique had started to develop in South Africa. Angelique had been to a designer but she couldn’t get any further. She had had the original idea to inject the pearls like a syringe but they didn’t work or injected more than one pearl one a time. After the team evaluation, a few problems were identified that needed to be solved for it to progress into the fourth prototype you see at the bottom of the picture. The problems that we put forward to solve were:

- The device needed to work and be ready for manufacture.

- They wanted the device to be operated with just one hand.

- Improved functionality to work with 3, 4, 5 mm balls.

- Insert of different hoppers for different sized balls.

- V shaped barrel to maintain alignment of different sized balls.

- Tighter silicone tip for better control

- Only one ball should be allowed to load into the barrel at a time

- Tilted hopper to ensure flow at different angles

- Improve style and shape of product where possible.

- Product should stand up on its own.

The development of this product

The team started designing a few examples of future prototypes and made them into a physical prototypes using 3DCAD and 3D printing.

A sample of the first prototype was then internally tested, fitted and made to work before having large-scale external testing. Gwen, who had an interest in baking herself gave the first prototypes to international bakers and artists for test and feedback. The most amazing bakers and artists in global cake events, had a feel of the dragéekíss, tested it and came back to us highlighting which options they preferred, what didn’t work so well and what functionally they were looking for in the dragéekíss.

External testing by international bakers.

The development process.

It was a long process of iterations and prototype development. Using our expertise and knowledge of working mechanisms, as the inside is a very small size for it to work properly, we did testing of prototypes and development of variations to test performance.

The team then conceived the design mechanism inside it for it to work adequately.

|

The old prototype at the top and the new one being tested out by the team.

The prototypes being examined against the CAD DESIGN to confirm accuracy.

|

- We had to consider how tight the plunger went in, how strong the clip that holds the balls was, and we faced the challenge of stopping other balls from going out at the same time.

- We had to select the correct spring to give the right feel but not be tiring to use. The spring was designed not to rust and be food safe.

- We had to adjust mechanisms to try to improve 3 mm balls ejection and retention.

- We added a small fraction of extra tolerance to reduce blockage from 5mm balls.

- The team brought forward the idea to make it stand up on its own and to make it suitable to be used with one hand for comfort.

- Food safe materials were chosen from manufacturers deciding to go for food safe PP to avoid nasty chemicals to pass to the food and ready to be washed at higher temperatures.

- We developed the plunger inside with a release clip. You can take the plunger out and clean it inside. Then reassemble it clicking it together so you know the applicator is ready to use again.

- We tested different material hardness for the silicone nozzle before going to a moulded part.

Several iterations of prototypes had to be developed and tested by the team and the amazing bakers at international baking shows.

Several iterations of prototypes were made to test functionality, movement, improvements and refine the tool.

From 3D PRINT TO INJECTION MOULDING IN PLASTIC.

injection mould product design

Prototype testing by renowned international cake artists.

One of the things that bakers gave us feedback for was that it was easier to press the plunger from the back rather than through the hole. So the next prototype was developed in accordance with this feedback.

Final product with circular plunger filled in. Nozzle made from food safe silicone rubber. The soft material grips the edible pearl allowing for controlled application onto the cake. The nozzle is designed to expand as the pearl is pushed through accommodating different sizes of pearls and creating the required control over delivery. The product is more elegant and stands out even more. Also we added the logo at the back of the tool and the “Made in Britain” stamp on the hopper.

The final design made a fully working product that fits into the cake market making it the must have tool.

Crowdfunding campaign:

Idea Reality provided a sales board, the manufacture drawings and crowdfunding videos for a successful campaign, we also designed packaging, and branding for a fully functional and attractive final product that stood out in the cake community.

Examples of animated 3D CAD used for the crowdfunding campaign and sales boards. Gwen used the videos, boards and animations for a presentation of the final product to potential customers surpassing her crowdfunding goals. This allowed her to mass manufacture her first 10,000 units of the DK.

She is currently selling the product through world distributors. From this she managed to grow a big audience who were eager to get the next product. A newer version that handles different sizes. Because it was so successful she decided to improve it even further.

Dragéekíss successes:

- Created own business

- Sold worldwide

- Fully crowdfunded

- Worldwide distributors

- Designed and made in the UK

Idea Reality helped with manufacturing, packaging, crowdfunding videos, and instruction booklets for marketing. This product has proven so successful that is being sold all over the world now.