PRODUCT DESIGN PROCESS

The process of product design and development.

Every invention idea is different, and therefore every product design process will be different. However, there are some typical stages and milestones every product design project will go through along the route to market, and the experienced team at Idea Reality are here to support you through every stage of your journey to making your invention idea a reality.

STANDARD PROCESS FOR BESPOKE PRODUCT DEVELOPMENT

1

Generating your invention idea

Working with you to brainstorm, research, and create the initial physical mock ups of your invention idea for testing where necessary; supporting you to understand and explore your idea before building the very first prototype.

2

Product concept design

Creating several variations of the product in order to efficiently and practically explore fundamental elements such as functionality, style and the logistics of manufacturing; typically involving at least 3 concept designs to maximise innovation before developing the chosen concept further.

3

Product concept development

Preparing your invention idea for prototype production; focusing all concept development efforts on the engineering of the product by creating 3D CAD models of all required parts, whilst ensuring any essential components are specified and sourced.

4

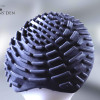

Design prototyping and construction

Taking the established concept and building a physical prototype with the aim of testing the design; identifying areas of improvement and further development, often using 3D printing or other production and fabrication processes depending on the materials used.

5

Prototype development

The CAD design is amended with any changes identified during the assembly and prototype testing process. Once complete, these updates may lead to the need for new parts or rebuilding the original prototype. It’s typical for several prototypes to be built in order to refine and perfect an invention design before progressing to manufacture.

6

Design for manufacture

Ensuring the process of mass scale manufacture is entered into and progresses both effectively & efficiently by creating a design for manufacture; making necessary adjustments to the proven product design, and providing specifications, 2d production drawings and any other material your preferred factory requires to complete the project in question.

7

Manufacturing assistance for product design

Supporting you to find, select, and communicate with manufacturers and factories to ensure the manufacturing process runs as smoothly and efficiently as possible; obtaining production costs, supporting, and advising you at every stage of manufacture to help guarantee the first batch comes off of the production line as you envisaged.

ELECTRONICS DEVELOPMENT PROCESS

1

Generating your invention idea

Working with you to brainstorm, research, and create the initial physical mock ups of your invention idea for testing where necessary; supporting you to understand and explore your idea before building the very first prototype.

2

Product concept design

Creating several variations of the product in order to efficiently and practically explore fundamental elements such as functionality, style and the logistics of manufacturing; typically involving at least 3 concept designs to maximise innovation before developing the chosen concept further.

3

Concept Development + Electronic Spec

Preparing your invention idea for prototype production; focusing all concept development efforts on the engineering of the product by creating 3D CAD models of all required parts, whilst ensuring any essential components are specified and sourced.

A detailed electronics specification is also created based on the project requirements and shared with yourself for approval. This will form the requirements to which the electronics are designed towards.

4

Electronic Hardware Design & Build

The electronics specification is shared with our electronics team to get PCB development and general electronic assembly underway. Upon completion of the stage you will be provided with a functional sample (additional may be requested for an extra fee).

4

Design prototyping and construction

Taking the established concept and building a physical prototype with the aim of testing the design; identifying areas of improvement and further development, often using 3D printing or other production and fabrication processes depending on the materials used.

5

Prototype development

The CAD design is amended with any changes identified during the assembly and prototype testing process. Once complete, these updates may lead to the need for new parts or rebuilding the original prototype. It’s typical for several prototypes to be built in order to refine and perfect an invention design before progressing to manufacture.

6

Electronics Development

The electronics (PCB and firmware) will likely need to iterated on in tandem with the rest of the product. This might be minor tweaks or complete redesigns and this will depend on the success of the prototypes and testing.

6

Design for manufacture

Ensuring the process of mass scale manufacture is entered into and progresses both effectively & efficiently by creating a design for manufacture; making necessary adjustments to the proven product design, and providing specifications, 2d production drawings and any other material your preferred factory requires to complete the project in question.

7

Manufacturing assistance for product design

Supporting you to find, select, and communicate with manufacturers and factories to ensure the manufacturing process runs as smoothly and efficiently as possible; obtaining production costs, supporting, and advising you at every stage of manufacture to help guarantee the first batch comes off of the production line as you envisaged.

FAST TRACK SOURCING EXISTING PRODUCTS OR PARTS

1

Design Specification

By producing a document covering each aspect of your intended product we can collate all the necessary information required to communicate effectively with our partners in stage 2. If you have provided us with this detail we can skip this stage.

2

Sourcing & Project Research

We will reach out to our network of suppliers and sourcing agents to try and identify existing products/components that can be bought in and modified/used for integration into your new design.

3

Continue with standard design steps if needed

Continue with Typical Process for any remaining custom parts needed or for bringing sourced items together in a bespoke casing for example

Your product design partners

As well as our in-house team of experienced product designers, Idea Reality has extensive workshop facilities at our premises, plus access to a network of specialist suppliers and prototype manufacturers; providing you with the knowledge, experience, and manufacturing contacts you need to make your invention idea a reality and bring it successfully to market.

Our experienced Hampshire-based product design team are here to guide, advise and support you from the initial concept design through to prototype and manufacture drawings.

Along with understanding the process and time implications you will also want an idea of costs. As the design has not yet been fully conceived it is impossible to quote exact costs but estimates can be given based on the type of product, size and complexity. Contact us for a free quotation

Free Idea Review

Got an idea for an innovative product? Get in touch to get your free idea review!

Free Advice Pack

Got an idea but don't know where to start? Click to get your free Inventor's Advice Pack!

We can also create bespoke packaging design for your product to stand out and enhance the user experience. If you need help with branding design such as logo’s, graphics and product launch websites just ask us to find out more.

Note: This is a simplified process and your project may require further stages and repetitions in order to achieve the best outcome.