Product Prototypes and Design Testing

Why prototype?

Test, modify and perfect your invention

An integral part of the process of making your invention idea a reality, creating product prototypes enables you to:

Prototype Construction

Building your product prototype

From tiny medical implants to large metal structures our team of design experts, together with the support of our extensive network manufacturers, are here to bring your prototype design and intention ideas successfully to market.

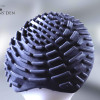

We offer cutting edge 3D printing and rapid prototyping services for rough mock-ups of concept designs all the way to final presentation prototypes, as well as prototypes for user testing and market research.

In addition, our experienced team also possess the capabilities and capacity to create prototypes for use in sales & marketing; producing market-ready prototypes for advertising, printed promotional material, and your website.

Prototype Testing

Prototype design testing

Prototypes allow for design testing and evaluation; identifying and therefore eliminating potential problems before mass manufacture. Prototyping highlights any challenges with the initial design, associated mechanisms or electronics, functionality and manufacturing process.

It can sometimes be an iterative process to perfect a series of prototype designs until it works as intended and is ready for production.

Prototyping therefore enables you to get your invention on the market as quickly, efficiently and cost effectively as possible and avoid mistakes or bad reviews.

Crowdfunding

Prototypes

PROTOTYPES FOR CROWDFUNDING, SALES AND INVESTMENT

High Fidelity prototypes & Hand Finishing for user feedback and sales Launch

We produce prototypes not only for testing purposes but also for sales such as crowdfunding campaigns. We have even built prototypes for TV advertising. In these situations the look and surface details must be of the highest quality.

Our design team has knowlege and access to some of the most advanced prototyping processes so whatever your requirements we have the experise to produce fantastic product prototype results.

Electronic Prototypes

Printed Circuit Boards and Programming

Design and assembly of custom PCB's and Electronic Circuits

We manage the full prototype process including electronic assemblies and components in order to make fully working product designs. Construction of Printed Circuit Boards (PCB) and integrated electro mechanical systems and IoT devices are part of our prototyping services here at Idea Reality.